Rewiring my HVAC to Maximize my EcoBee's Control Capabilities

Ben Houston • 8 Minutes Read • January 14, 2026

Tags: hobbies

As a software engineer, I'm used to having full visibility and control over the systems I manage. If a process hangs, I check the logs. If a job is inefficient, I optimize the code. But recently, I realized the most expensive and critical system in my house, my HVAC, was operating like a black box running legacy code I couldn't touch.

The system felt sluggish. There were long pauses before heating kicked in, and the house never seemed to warm up quickly on the coldest Ottawa nights. But I didn't know why.

I'd actually brought this up with my HVAC technician. I have a maintenance contract where they come by twice a year to check the equipment. His response was unhelpful: he didn't see an issue, said it seemed to be working fine. Classic "works on my machine" energy.

So I decided to treat this like debugging an unfamiliar codebase: understand the system first, then identify the problems myself.

Phase 1: Reverse Engineering & Discovery

Before touching a single wire, I spent hours taking pictures and tracing lines. I mapped every connection between the Furnace, the Thermostat, the HRV, the HRV controller, the Heat Pump, and the Humidifier. I identified what equipment I had specifically and read their manuals. This was critical—I needed to fully understand the existing setup and know how to restore it if I messed things up.

What I discovered was enlightening.

The Legacy Stack: "Spaghetti Code" in Hardware Form

My system consisted of a Daikin AC/heat pump and a dual-stage gas furnace (with blower fan), plus a Clean Comfort HRV and a flow-through humidifier. Tracing the wiring revealed three major architectural problems:

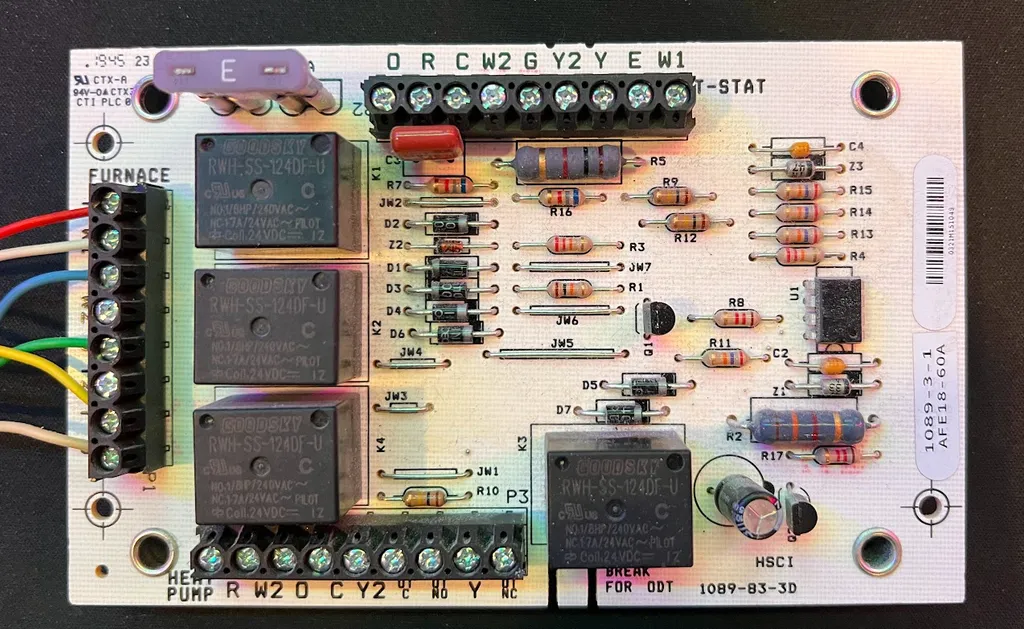

1. The Middleware: The Fossil Fuel Kit

The installer had wired the system through a Fossil Fuel Control Board. In software terms, this board was a middleware layer that intercepted signals from the thermostat and decided for me what to run. It was connected to an exterior thermostat located on the Heat Pump. I suspected this was the likely culprit for the sluggish system control. It introduced hard-coded delays and timeouts that conflicted with the Ecobee's smarter algorithms. It effectively prevented the Ecobee from knowing whether it was burning gas or spinning the heat pump.

2. The Bandwidth Bottleneck

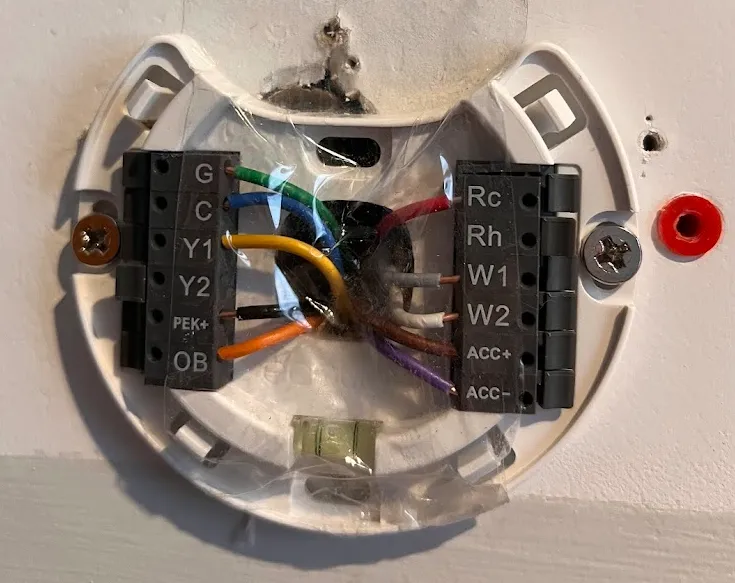

The existing 18/6 wire (6 individual wires of 18 gauge) running from the mechanical room to the thermostat was insufficient. It didn't have enough conductors to control the Heat Pump, Furnace (Stage 1 & 2), Fan, Humidifier, and HRV simultaneously.

This explained something I noticed: the W2 terminal on the Ecobee wasn't connected to the Furnace's W2. There simply wasn't a spare wire available. My dual-stage furnace was stuck running only Stage 1 heat. No wonder the house struggled to warm up quickly on cold days.

3. The "Dumb" Peripherals

Because of the limited wiring, the peripherals were isolated from the Ecobee entirely:

- The HRV was running on a manual wall controller. It was either "Off" or running "20 minutes/hour" regardless of air quality.

- The Humidifier relied on a manual humidistat in the basement, meaning it couldn't adjust itself based on the outdoor weather.

The Plan: Fix the Problems, Maximize the Potential

At this point, I had my diagnosis. The Fossil Fuel Kit was likely causing the sluggishness, and the missing W2 wire explained the slow heating. But I also realized something else: if I was going to run new wire anyway, I might as well run enough to unlock everything the Ecobee Premium could control. Why stop at fixing problems when I could maximize the system's capabilities?

The goal became: deprecate the legacy middleware and give the Ecobee direct, full-stack control of heating, cooling, ventilation, and humidity.

Phase 2: The Refactor (Incremental Rollout)

I didn't want to do a "big bang" release and leave my family without heat if it failed. I deployed the changes in incremental stages, verifying stability after each step. Crucially, after each change, I updated Ecobee's configuration and then used its built-in equipment testing mode to verify the new capability worked before moving on, the equivalent of running a test suite after each commit.

- Removal of Middleware: I removed the Fossil Fuel Kit first, wiring the heat pump and furnace to the existing thermostat wires to confirm the basic dual-fuel logic worked without the extra board. I also removed any connections to the outside thermometer that was previously wired into the Fossil Fuel kit.

- Infrastructure Upgrade: I ran a new, beefy 18/10 low-voltage wire through the walls. This upgraded the system's bus width to handle all necessary signals.

- Feature Add (HRV): I wired up the HRV to the ACC+ / ACC- terminals and removed the old manual controller and adjusted the Furnace interlock settings. This was a little complex and required reading the manual to fully understand how to configure it on the 4 controller terminals (in the end ACC+ connected to R and ACC- connected to G.)

- Feature Add (Humidifier): I wired the humidifier solenoid to the PEK terminal (and the C common terminal to complete the circuit), removing the basement humidistat.

- Add Stage 2 Heating: I added the wire from W2 on the Thermostat to the Furnace to enable fast heating.

The New Architecture: Direct Control

The Ecobee now acts as the central CPU in control of everything. The end result is:

- Heat Pump (Cooling/Heating): Primary efficiency layer.

- Furnace Aux Stage 1: For when it gets too cold for the heat pump.

- Furnace Aux Stage 2: High-power heating for rapid recovery.

- HRV (Ventilator): Wired for automated air quality and cooling.

- Humidifier: Wired for automated winter humidity regulation.

Technical "Gotchas"

If you are planning to attempt this, here are the edge cases I encountered.

1. The "Pro" Menu is Mandatory By default, Ecobee assumes you only have one accessory. To control both a Humidifier and a Ventilator, I had to unlock the "Pro" setup menu.

2. The Critical Safety Lockout (Heat Pump vs. Furnace) In my system, the heat pump coils sit after the furnace burners. If you run the Gas Furnace and the Heat Pump at the same time, the furnace will blast the heat pump coils with extreme heat, potentially destroying the compressor. You must configure the Ecobee to never run Aux Heat and the Heat Pump simultaneously.

3. The Defrost Exception The exception to the rule above is the Heat Pump's "Defrost Mode," which runs A/C in the winter to melt ice on the outdoor unit. This shoots cold air into the house.

- The Fix: The Heat Pump has a W terminal that sends a signal when it's defrosting. I wired this directly to the Furnace's W1. This acts as a hardware interrupt, triggering the furnace only during defrost to temper the air, bypassing the Ecobee completely.

4. DIP switches on the Furnace There are 20 DIP switches on the Furnace control board. From reading the manual later, I found that one could have setup the furnace to automatically switch to Stage 2 heating if a Stage 1 heating run lasts long enough. This wasn't set on my furnace by the installers but it should have been given I only had a W1 line configured.

The Results

The difference was immediate and the efficiency gains were significant.

- Comfort: The house heats up faster because the Ecobee can now engage Stage 2 Gas Heat when the temperature delta is high. The HVAC system in general is more responsive as well since the delays and timeouts from the Fossil Fuel kit are removed.

- Air Quality: The Ecobee monitors air quality sensors. If CO2 or VOCs rise, it pulses the HRV automatically. No more guessing with manual timers.

- Winter Efficiency: The Ecobee uses the HRV as a "dehumidifier" by cycling dry outside air in, rather than running a separate dehumidifier.

- Summer Efficiency (Free Cooling): This should be a huge win, although I have to wait for summer to really see the impact. If the house is hot but the air outside is cool (e.g., a summer night), the Ecobee will now run the HRV to pull in cool air rather than turning on the expensive Air Conditioner compressor.

- Smarter Humidification: The Ecobee adjusts the humidity setpoint based on the outdoor temperature (Frost Control) to prevent condensation on windows.

The One Manual Annoyance: Despite all this automation, I still have to walk downstairs twice a year to physically flip the damper on the humidifier between "Winter" (Open) and "Summer" (Closed). Software can't fix everything, yet.

What's Missing (Feature Request for Ecobee)

While the control is better, the observability is still lacking.

- Vague Graphs: Ecobee's data logs group "Heat Pump" and "Aux Heat" too broadly.

- No Accessory Logging: There are no graphs for when the Ventilator or Humidifier runs.

- Air Quality vs. Action: It measures air quality, but doesn't overlay "Ventilator Active" on the Air Quality graph.

Future Thoughts

Pulling that 18/10 wire felt archaic. In 2026, I wonder why we can't have a hub at the furnace that communicates with the thermostat via a digital protocol, rather than running all the wires up and back down. It would save a massive amount of installation effort and allow for infinite expandability.

Common Questions

Q: Do I need to be a licensed electrician to do this? A: Generally, no. Thermostat wiring is "Low Voltage" (24V). However, always turn off the furnace, heat pump, and ventilator breakers before touching wires to avoid blowing a fuse on the control board.

Q: How do I know if I have a Fossil Fuel Kit? A: Trace your thermostat wires. If they go into a separate small circuit board before they go into the main furnace board, you likely have a dual-fuel kit.

Q: Can this damage my Heat Pump? A: Yes, if configured wrong. As mentioned in the "Safety Lockout" section, you must ensure the Ecobee is set to Disable "Allow Aux Heat to run with Heat Pump" to prevent overheating the compressor.

Q: Does DIY thermostat wiring void your furnace or heat pump warranty? A: Generally, no. In the US, the Magnuson-Moss Warranty Act (and similar consumer protection principles in Canada) prevents manufacturers from voiding a warranty simply because you performed your own work. They would need to prove that your modification directly caused the specific failure. Rewiring the thermostat connections doesn't change how the equipment itself operates. It just changes who's making the decisions. That said, if you misconfigure the safety lockout and fry your compressor, that's on you.